1. Optimize coagulant/flocculant dosing.

2. Increase settling time or add a sedimentation step.

3. Enhance filtration efficiency.

4. Implement advanced treatment processes like membrane filtration.

5. Regularly monitor and adjust treatment parameters.

6. Investigate source of TSS and implement source control measures.

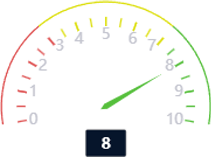

Complete System

Chem Precipitation

PH Adjustment

ASP

Clarifier

Ultra Filtration

RO

| Alert Name | Suggested Action | Alert Date |

|---|

| PM for FEED PUMP (P16-A) DISCHARGE PI |

1) Inspect seals, gaskets, and other connections for wear, damage, or leaks. Replace any components that show signs of deterioration. 2) Pressure Range Verification and Calibration of instrument |

2024-04-25 10:00:00 |

| PM for FEED PUMP (P19-A) DISCHARGE PI |

1) Inspect seals, gaskets, and other connections for wear, damage, or leaks. Replace any components that show signs of deterioration. 2) Pressure Range Verification and Calibration of instrument |

2024-04-10 10:00:00 |

| PM for FEED PUMP (P21-A) DISCHARGE PI |

1) Inspect seals, gaskets, and other connections for wear, damage, or leaks. Replace any components that show signs of deterioration. 2) Pressure Range Verification and Calibration of instrument |

2024-04-15 10:00:00 |

| Alert Name | Suggested Action | Alert Date |

|---|

| ASP module is deteriorating |

1. Optimize waste sludge withdrawal. 2. Increase influent flow rate. 3. Improve aeration efficiency. 4. Optimize F:M ratio 5. Enhance biomass retention in clarifier 6. Enhance return activated sludge (RAS) flow 7. Adjust solids retention time (SRT) to enhance MLSS concentration |

2024-03-28 13:05:00 |

| Clarfier perfromance is detirorating |

1. Increase hydraulic retention time. 2. Reduce recirculation rate 3. Check the Bottom SV of clarifier 4. Follow MLSS to MLVSS ratio 5. Monitor and adjust sludge removal rate |

2024-03-28 18:45:00 |

| Chemical Precipitation Module TSS is deterioraing |

1. Optimize coagulant/flocculant dosing. 2. Increase settling time or add a sedimentation step. 3. Enhance filtration efficiency. 4. Implement advanced treatment processes like membrane filtration. 5. Regularly monitor and adjust treatment parameters. 6. Investigate source of TSS and implement source control measures. |

2024-03-28 09:25:00 |

| Alert Name | Suggested Action | Alert Date |

|---|

| ASP MLSS is high, sludge carryover is there in clarifier | Adjust solids retention time (SRT) to enhance MLSS concentration | 2024-03-28 13:05:00 |

| Cod redcution is lower than 60% |

1. Increase hydraulic loading rate. 2. Adjust chemical dosing for optimal coagulation. 3. Optimize clarifier flocculation. 4. Minimize turbulence in clarifier 5. Increase detention time 6. Adjust sludge blanket depth 7. Monitor and adjust sludge withdrawal rate |

2024-03-28 18:45:00 |

| Clarifier bottom SV is low |

1. Monitor and adjust sludge recirculation 2. Increase MLSS 3. Increase DO level in biological process 4. Monitor and adjust the Recirculation. |

2024-03-28 09:25:00 |

| High TSS in Chemical outlet |

1. Adjust coagulant and flocculant dosing 2. Monitor and adjust inlet PH |

2024-03-28 09:25:00 |